About Wuxi Qijue

Founded 2019, Wuxi Qijue Vehicle Industry Co., Ltd. operates a 20,000 m² headquarters in Wuxi, China with approximately 50 staff (20% R&D, 50% production, 30% support). Annual production capacity: 20,000 units. Annual revenue: RMB 100M+. We export to 50+ countries with National High-Tech Enterprise certification, ISO9001, ISO14001, EEC, CE, and GSO compliance. Our facility includes in-house battery production and full industrial-chain manufacturing capabilities.

Credentials & Compliance

Verified certifications and intellectual property portfolio

Certifications

Patent Portfolio

Manufacturing Excellence

Comprehensive capabilities spanning production, innovation, and quality assurance

Flexible Vehicle Production

Two production bases with three lines. Wuxi base produces electric motorcycles and large scooters with 30,000 units annual capacity, handling both large-volume and small-batch custom orders. Zhejiang Yongkang base under construction for electric four-wheel ATVs.

In-House Battery Production

Independent battery line at Wuxi base producing 80% of battery needs in-house. Semi-automated processes cover cell selection, welding, BMS integration, and sealing tests. Supports ranges from 50 to 300 km with rigorous quality control including temperature, collision, compression, and penetration testing.

Advanced R&D Capability

RMB 20 million invested in full-cycle electric motorcycle R&D. End-to-end development from concept to validation with 10+ years experienced engineers. Advanced testing facilities include power testing, range simulation, environmental labs, and vibration testing. Self-developed high-power mid-drive chain motor system achieving 200 km/h top speed.

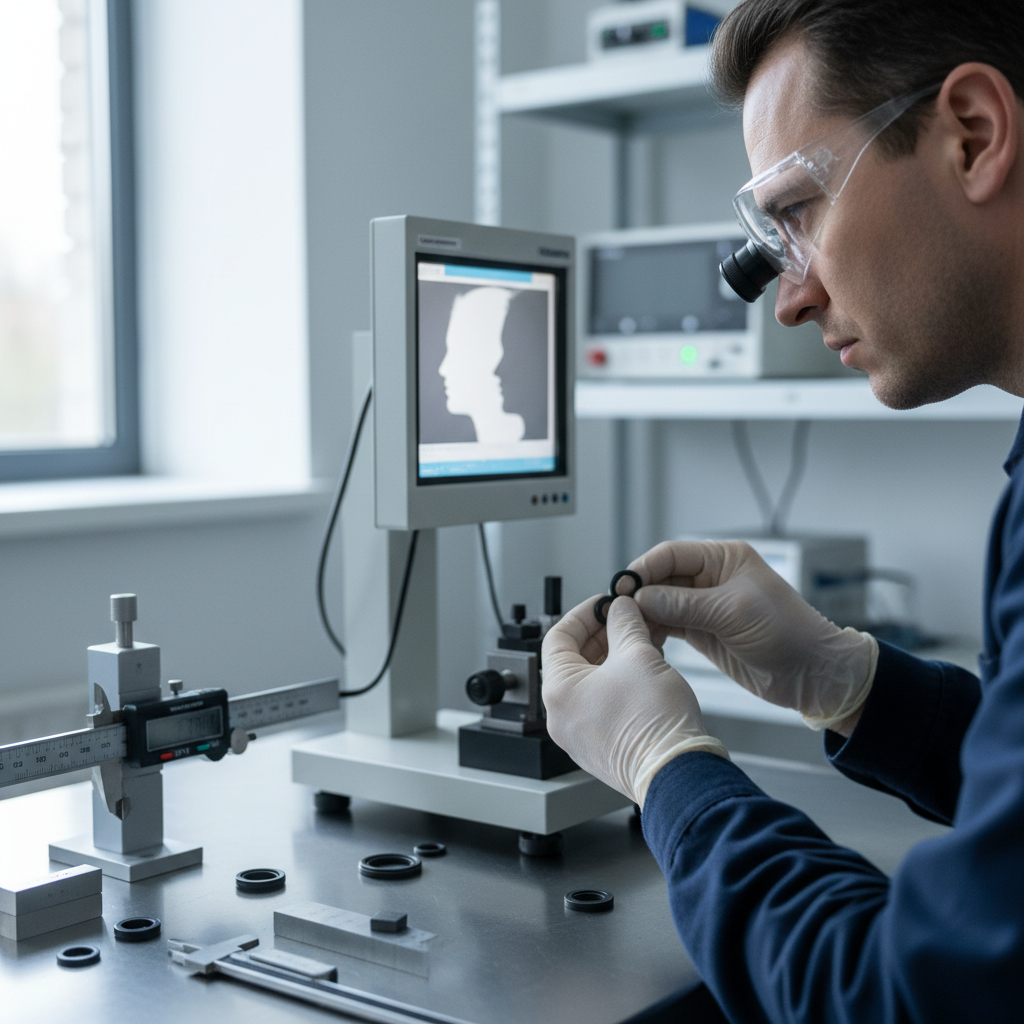

Comprehensive Quality Control

All battery cells undergo full inspection for resistance, voltage, and capacity. Finished packs rigorously tested for temperature endurance, collision resistance, compression, penetration, and charge-discharge cycles. EEC and U.S. DOT certifications for 3 product series with nearly 10 models.

Manufacturing at Scale

Proven track record of excellence and global impact

Units manufactured yearly

Countries served

20% R&D, 50% production, 30% support

5 invention, 3 utility, 15 design

Wuxi headquarters

RMB revenue

Ready to Build Your Electric Mobility Business?

Join our global network of successful distributors and partners. Experience manufacturing excellence, technical innovation, and dedicated support that drives mutual success.